Milling and homogenisation are terms for the mixing of inhomogeneous substances.

Milling is the process of reducing the particle size of a material. Grinding therefore means reducing a product so that it is homogenous enough to the desired size.

Crushing, on the other hand, is a coarser process. It means to reduce the grain size of a material without necessarily making it homogenous at the end of the process. Crushing means reducing but there may be pieces of different sizes.

Milling and homogenisation

.

Milling and homogenisation in the laboratory may be necessary. Especially if you want to precisely determine the final size of the compound.

When the particle size reduction is less than 100 microns, the correct term used is micronisation. If larger, it can be called pulverisation.

In fact, the term grinding is usually used when reducing a material to a powder. For example coffee or often food.

Crushing on the other hand often refers to stones.

Homogenisation

We have spoken of grinding and homogenisation to indicate general principles. This second process is based on the principle of making a mixture that is not homogenous.

When a compound is the same in every part, it can be called homogenous. If, on the other hand, the mixture shows different concentrations, then it cannot be called homogenous.

Homogenisation is therefore a part of the mixing process in general.

Specifically, it involves mixing insoluble parts together to form a suspension or emulsion.

Think of the mayonnaise process, for example.

The homogenisation process is based on the principle of homogenisation.

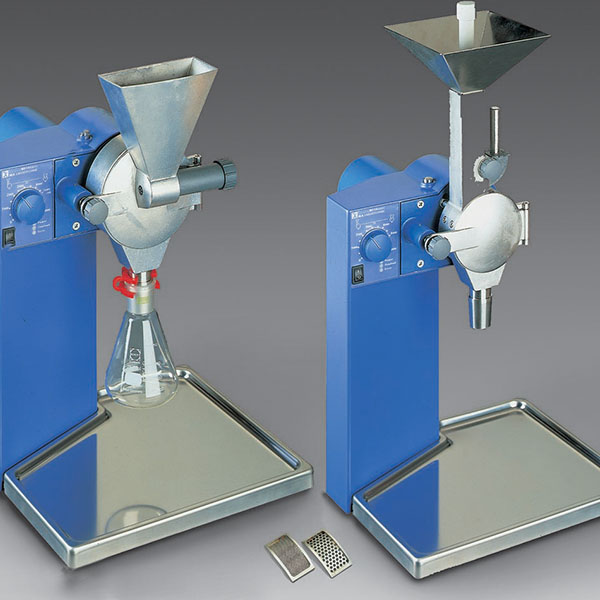

There is a wide range of laboratory crushers and mills on the market for processing different samples.

Milling tools range from the pharmaceutical laboratory mill used for preparing powders, to industrial crushers for inert materials and waste.

Milling is a useful process both in the analysis laboratory and in a processing industry. In any situation where it is necessary to prepare a sample precisely.

.

The dispersion tools

Homogenisers can be equipped with different dispersion tools. Each of these has a shape that makes it suitable for obtaining different results and for different volumes. Each allows final emulsion and suspension particle sizes expressed in µm.

The tools must of course be sterilisable by all methods.