Thermostatic baths are stainless steel tanks with liquid in which containers are immersed. This liquid must be maintained at a constant temperature in order to heat the contained containers.

Baths are used in analyses where several containers need to be heated evenly and simultaneously.

The baths are usually maintained at temperatures of 60 to 90 °C. Their advantage lies in the speed of heating.

.

Thermostatic baths or flame heating?

.

Thermostatic bath heating is better. Heating with a flame like the Bunsen burner exposes you to excessive heating. In addition, splashing and decomposition of the substance to be heated is avoided.

What do thermostatic baths look like?

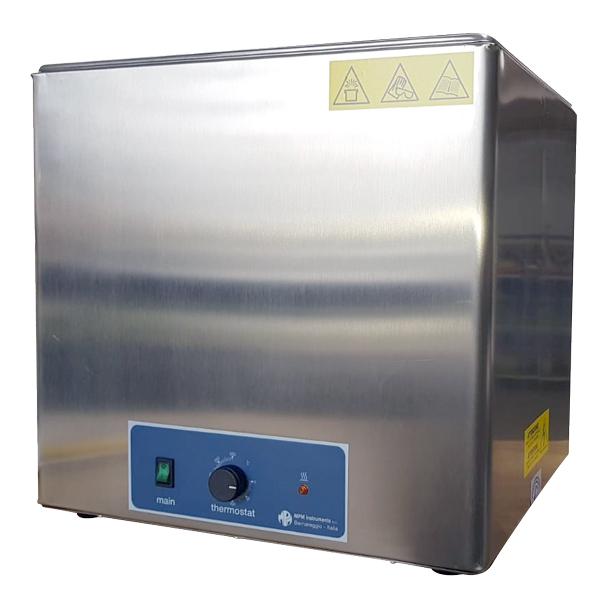

The external structure of thermostatic baths is almost always made of insulating material. Stainless steel baths have a drain tap to empty the water.

The baths are made of stainless steel.

To maintain the thermal insulation of the bath, fibreglass is inserted between the outer structure and the bath as insulation.

There are versions with a lid to further insulate the temperature of the liquid.

The temperature is regulated and maintained by a thermostat.

Different types of baths

.

Baths can be

.

- with water,

- oil-based

- sand

.

The choice is made according to the material being heated to maintain the temperature.

Water baths reach temperatures of 120°C in a short time, while oil baths can reach temperatures of up to 400°C.

Sand baths are ideal for homogeneous heating or evaporation.

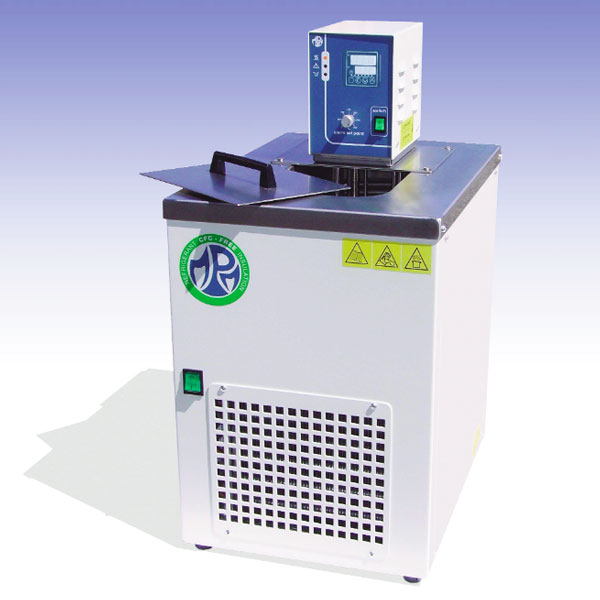

There are baths such as immersion baths, which have the special feature of having an external heating element (head with heating element) that can be adapted to different containers.

This element can be equipped with digital programming, which makes the processes very repeatable.

On the market, there are models that accommodate a single container or several at once, and the choice is determined by the quantity of containers that need to be kept at temperature.