Crucibles are equipment used in laboratories as containers for chemical compounds that need to be heated to high temperatures. They are extremely common and have been used by man since the sixth millennium BC. Although their shapes and sizes have varied over time, depending on their various uses, they have always been used by man. In fact, models of them have been found dating back to the Stone Age and the medieval period. In modern chemistry, they have been developed to have the best performance conditions in resisting high temperatures.

Shape and Measurements of Crucibles

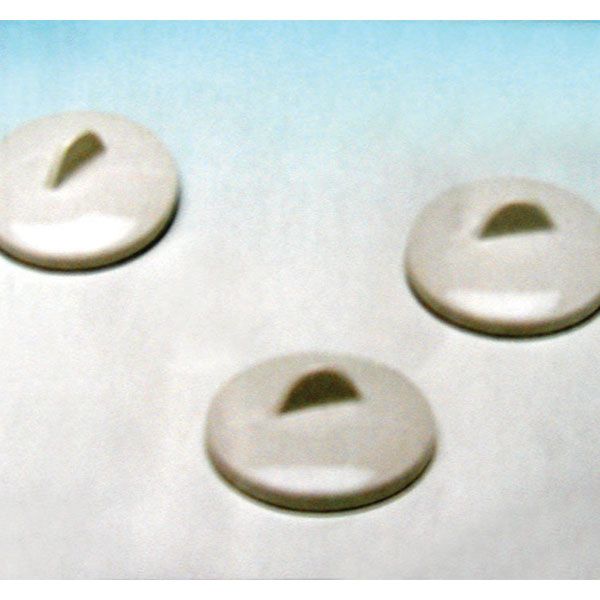

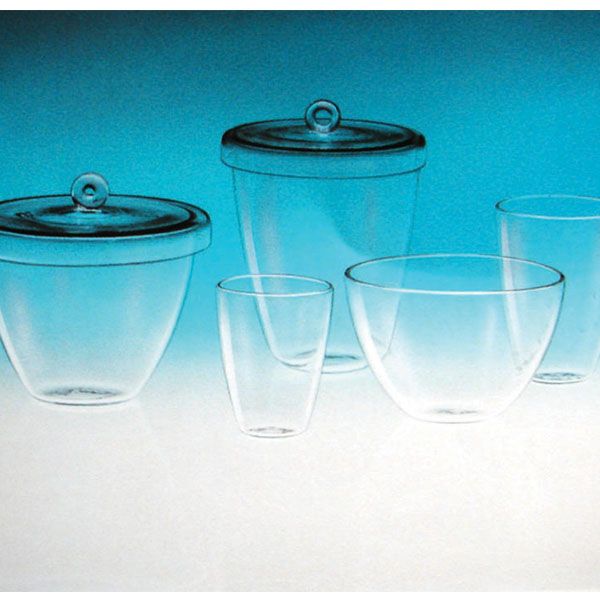

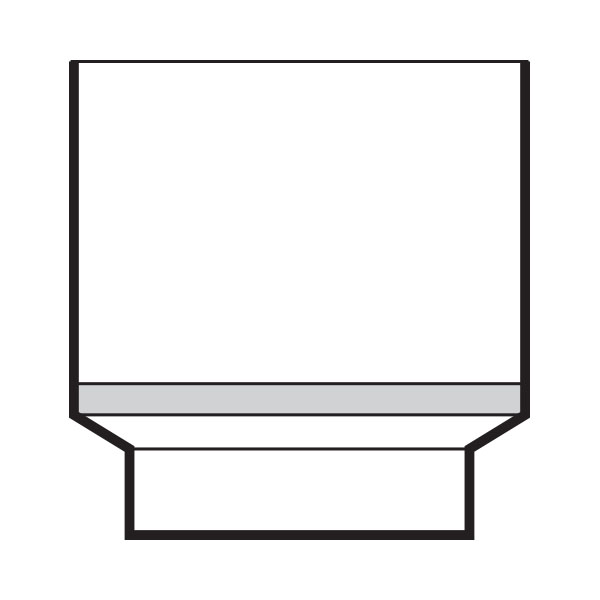

As previously pointed out, crucibles have had various shapes and sizes in their development. However, the standard design used in modern chemistry is characterised by a truncated cone shape with a flat bottom. They generally have a diameter of between 3 and 5 cm, and are fitted with a lid. It is important to note that the lid is not hermetically sealed. This is because during the heating process of the substances contained in the crucible, these produce gases that the lid allows to escape. If this were not the case, and the lid hermetically sealed to contain the gases, dangerous situations would arise, given the high pressure inside the equipment.

There are models in taller and narrower variants, and others in shallower and wider variants, depending on their use in the laboratory.

Materials

Initially, the first man-made crucibles were made of clay. With time and scientific development, the material of crucibles changed in order to offer better performance characteristics.

Because crucibles must be subjected to high temperatures, their material must be resistant. Consequently, crucibles are now generally made of porcelain, aluminium or inert metals. In fact, one of the first uses of platinum was to form crucibles. In modern chemistry, there are also other models made of nickel and zirconium.

Accessories

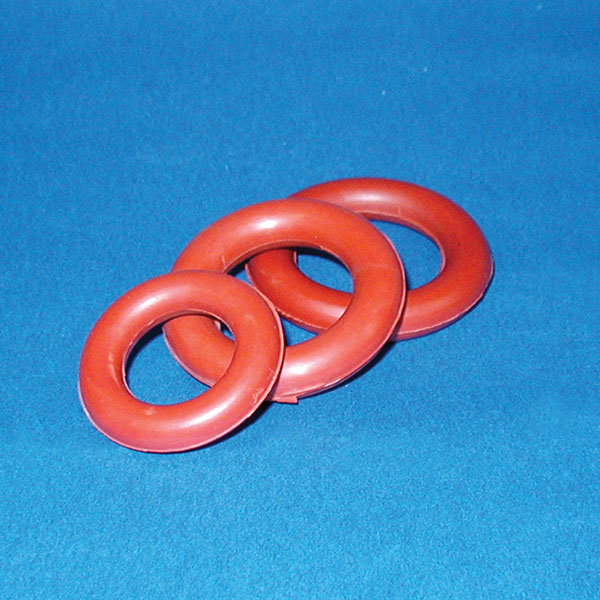

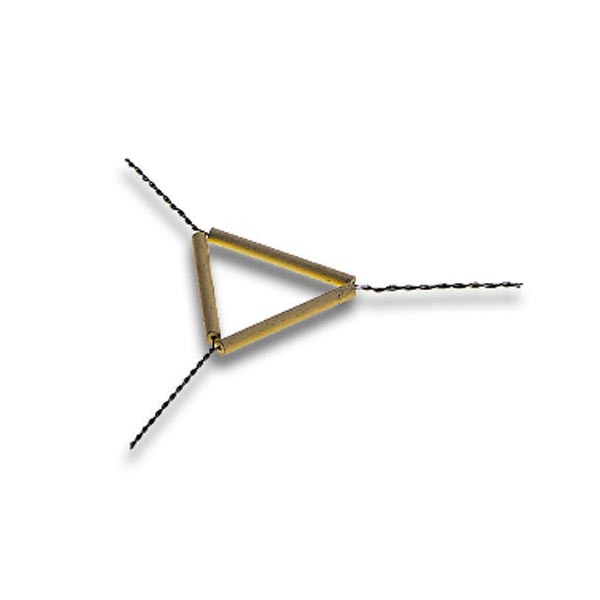

There are accessories that are indispensable when using crucibles, which come into direct contact with the flame of the Bunsen burner. Galvanised iron triangles, for example, consist of the structure that holds the crucible when placed over the flame. These consist of three galvanised iron clips connected to refractory bars. In turn, the galvanised iron triangles, which support the crucible, are inserted into the tripod to ensure the correct height above the flame.

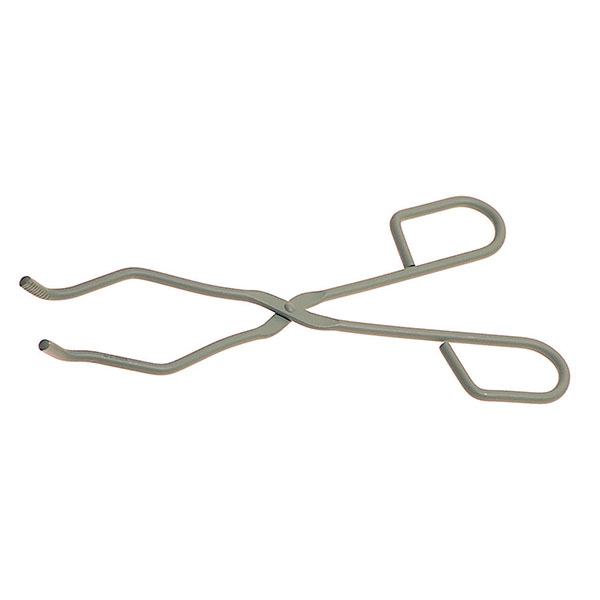

In addition, tongs are also used to handle the crucibles when they reach a high temperature. The tongs are usually made of steel, but can also be coated with polytetrafluoroethylene (PTFE).